Globe Valve

1150.00 INR/Piece

Product Details:

- Life Span Long Service Life

- Style Bolted Bonnet

- Pressure PN 10 / PN 16

- Condition New

- Capacity Suitable for Industrial Piping Applications

- Output Manual Flow Control

- Fuel Type None

- Click to View more

X

Globe Valve Price And Quantity

- 20 Piece

- 1150.00 INR/Piece

Globe Valve Product Specifications

- Long Service Life

- Globe Valve

- Cast Iron

- Bolted Bonnet

- PN 10 / PN 16

- New

- Varies by model (Contact Supplier)

- Flow Control

- Suitable for Industrial Piping Applications

- None

- Manual Flow Control

Globe Valve Trade Information

- 1 Piece Per Week

- 7 Days

- Yes

- Contact us for information regarding our sample policy

- Carton Boxes, Wooden Box

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- ISO Certified

Product Description

We Offer A Wide Assortment Of Non Ibr & Ibr Boiler Valve Mounting Accessories To Our Clients At Competitive Market Prices. These Valve Mounting Accessories, Manufactured Using Superior Quality Raw Materials, Are Acknowledged For Their Better Service Life And High Tensile Strength. These Devices Are Used Extensively In Industries Like Petrochemical, Chemical, Industrial, Marine And Infrastructure.Features :

- Safety Valve (Ibr & Non Ibr)

- Blow down Valve (Ibr)

- Fusible Plug (Ibr)

- Steam Stop Valve (Ibr & Non Ibr)

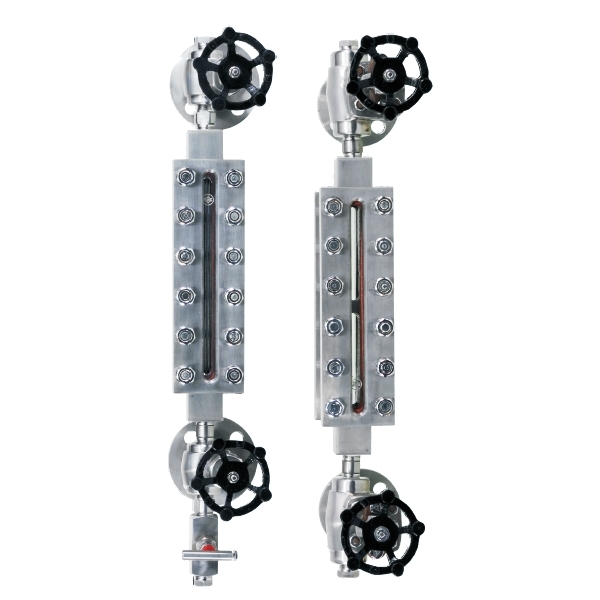

- Relex Gauge Glass Assembly (Ibr & Non Ibr)

- Mobrey Water Level Controller (Ibr & Non Ibr)

- Man Hole & Mud Hole Gasket

- Non Return Valve (Ibr & Non Ibr)

Reliable Flow Control Solution

Engineered for precision, this globe valve ensures reliable manual regulation of fluid flow in industrial environments. The robust cast iron construction, coupled with a choice of renewable brass or stainless steel seats, provides stability and resistance to demanding conditions. Its compatibility with multiple fluidssuch as water, steam, oil, and gasmakes it a flexible option for diverse applications.

Built to International Standards

Manufactured to meet ISI and BS standards, these valves guarantee consistent safety and operational performance. The rising stem and OS&Y design facilitate clear visual verification of the valves status, contributing to enhanced on-site safety during maintenance or operation. Flanged ends offer ease of installation, and the bolted bonnet design simplifies servicing.

FAQs of Globe Valve:

Q: How does the handwheel operation of the globe valve work?

A: The globe valve features a manual handwheel that allows the operator to precisely control the flow of fluids by turning the wheel, which moves the rising stem and regulates the valve opening.Q: What applications are suitable for this globe valve?

A: This valve is designed for industrial piping systems and is suitable for controlling the flow of water, steam, oil, and gas across a wide range of industries.Q: When should a Class VI (bubble-tight) leakage rated globe valve be used?

A: Use a Class VI leakage rated globe valve when you require maximum tightness, ensuring no detectable leakage in critical applications where valve integrity is paramount.Q: Where can this globe valve be installed?

A: It can be installed in any pipeline that supports fluid control, such as water treatment plants, oil refineries, steam distribution networks, and gas transmission systems.Q: What is the process for selecting the correct valve size?

A: To select the appropriate size, review the pipeline diameter and flow requirementschoose from available sizes (50mm to 300mm) to ensure optimal performance for your specific application.Q: How does the renewable seat benefit the user?

A: A renewable seat design allows the seat to be replaced when worn, extending the valves service life without needing to replace the entire unit, resulting in lower maintenance costs and downtime.Q: What are the main benefits of the OS&Y (Outside Screw & Yoke) rising stem design?

A: The OS&Y rising stem design offers visual indication of the valves open or closed position, making it easier and safer to operate and maintain, particularly in industrial settings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese